Wire Rope Inspection Process

Wire ropes are an essential component in many industries including construction, mining, and maritime operations. They bear the weight of heavy loads, making their structural integrity vital for daily operations.

This blog post explores the importance of regular wire rope inspections. Let's delve into the reasons why regular wire rope inspections are so important to maintaining safety on-the-job!

Why Regular Wire Rope Inspections are Critical

Wire ropes endure extreme wear and tear during their service life. Over time, defects and damage can compromise their integrity, leading to potentially catastrophic consequences. The use of damaged wire ropes can result in accidents, injuries, and even loss of life, not to mention the legal and financial liabilities for companies.

Loss of productivity is another result of defective wire ropes, bringing operations to a grinding halt, causing delays, project setbacks, and significant financial losses. Regular inspections serve as the first line of defense against these dangers, allowing issues to be identified and addressed before they escalate.

Key Steps in the Wire Rope Inspection Process

Effectively mitigating these risks requires understanding the wire rope inspection process. There are various inspection methods, including visual inspections, non-destructive testing (NDT), and magnetic particle inspections. Robust documentation and record-keeping are essential for tracking the condition of wire ropes over time, facilitating timely maintenance and replacements.

Equally crucial to the inspection process is having the right tools and equipment. Inspectors rely on specialized gear such as wire rope gauges to accurately assess wire rope conditions. These tools ensure thorough and reliable inspections, reducing the chances of missing potential issues.

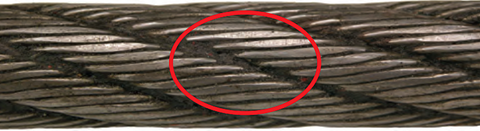

1. Visual Inspection: This is to check for signs of distortion such as wave-distortion, bird caging, core rope displacement, swelling or constriction.

2. Cloth Rag Testing: The inspector may pull a rag along the rope in aims to identify any broken wire cords.

3. Wire Rope Diameter Calculation: Diameter reduction is a key factor in steel wire rope wear & can result in rope breakage. Excessive abrasion, loss of core mass, corrosion or inner wire failure are all factors that contribute to diameter reduction.

4. Abrasion, Corrosion, Pitting & Deep Lubrication Check: Failure due to abrasion or corrosion can be the result of insufficient wire rope lubrication.

Best Practices for Conducting Effective Wire Rope Inspections

Effective wire rope inspections demand trained and certified inspectors who grasp the intricacies of these components. Regular training and certification programs keep inspectors updated on industry standards, trends and techniques, enhancing their ability to identify and address issues effectively.

Routine inspections and maintenance are non-negotiable. Creating and adhering to a strict inspection schedule prevents surprises and empowers companies to proactively manage their wire rope assets. Furthermore, strict adherence to manufacturer guidelines and industry standards is essential. Deviating from these recommendations can jeopardize safety and lead to unexpected failures.

Conclusion

To summarize, wire rope inspections are not merely a regulatory requirement; they are a fundamental practice for industries reliant on wire ropes. Neglecting inspections can result in dire consequences, both in terms of safety and financial impact. Prioritizing wire rope inspections in our industries is imperative, acknowledging their critical role in preventing accidents, reducing downtime, and safeguarding our workforce.

We must commit to regular inspections, certification, and adherence to best practices to secure the integrity of our wire ropes and the safety of our operations. Your dedication to this vital process can save lives, protect your business, and ensure a more secure future for your industry. By investing in wire rope inspections, you invest in safety, longevity, and the continued success of your operations.