Elevating Safety & Efficiency with Web Slings

At MTN Industrial, we are committed to providing superior lifting solutions that prioritize safety and efficiency. Our selection of web slings caters to a wide range of lifting needs, ensuring compliance with rigorous standards and delivering unparalleled performance in diverse operating conditions.

Understanding Web Slings: An Overview

Web slings are a crucial component in many lifting operations, offering a flexible, lightweight, and cost-effective alternative to traditional chain or wire rope slings. Made from woven synthetic materials, web slings are designed to evenly distribute the load, reducing the risk of damage to the load and enhancing safety during lifting.

Key Features and Benefits of Web Slings

Versatility: Web slings are highly adaptable, capable of being used in various hitch configurations, including vertical, choker, and basket hitches.

Weight and Flexibility: Compared to chain and wire rope slings, web slings are significantly lighter and more flexible, making them easier to handle and less likely to cause injury or damage to delicate surfaces.

Safety: The broad surface area of web slings helps to distribute the load over a larger area, reducing the risk of pressure points that can cause damage to the load or the sling itself.

Durability: Modern web slings are engineered with advanced materials and protective features to withstand tough lifting environments, ensuring long service life and consistent performance.

Material Differences: Nylon vs. Polyester Web Slings

When choosing web slings, understanding the differences between nylon and polyester is crucial as each material offers unique properties suitable for different applications.

Nylon Web Slings

Elasticity: Nylon slings are known for their elasticity, which allows them to absorb shock loads. This makes them ideal for applications where loads are subject to dynamic forces or sudden movements.

Chemical Resistance: Nylon has good resistance to a range of chemicals, but it can be adversely affected by acids and bleaching agents. It performs well in applications where exposure to alkaline is expected.

Moisture Absorption: Nylon can absorb water, which can affect its strength when wet. However, it dries quickly and regains its full strength once dry.

Temperature Resistance: Nylon slings degrade at temperatures above 200°F and should not be used in environments where they are exposed to continuous high heat.

Polyester Web Slings

Low Stretch: Polyester slings have minimal stretch under load, providing a more stable lifting experience. This makes them suitable for applications requiring precise load positioning and minimal movement.

Chemical Resistance: Polyester has excellent resistance to acids and other harsh chemicals but is less resistant to alkaline environments compared to nylon.

Moisture Resistance: Polyester does not absorb water and maintains its strength in wet conditions, making it ideal for use in environments where exposure to moisture is a concern.

UV Resistance: Polyester slings offer superior resistance to UV degradation, making them more durable for outdoor applications.

Design Differences: Round vs. Flat Slings

In addition to material differences, web slings also come in various designs, with round and flat slings being the most common. Each design has distinct advantages and is suited to different lifting scenarios.

Round Slings

Construction: Round slings are made from a continuous loop of high-strength fibers encased in a durable cover. This design offers a high degree of flexibility and conformity to the load's shape.

Load Distribution: The circular shape of round slings allows them to distribute the load evenly around the sling, reducing wear and tear on the fibers and increasing the lifespan of the sling.

Load Capacity: Round slings can accommodate very high load capacities relative to their size and weight, making them ideal for heavy lifting applications.

Ease of Use: Their soft and flexible nature makes round slings easy to handle and reduces the risk of damage to delicate or finished surfaces.

Inspection: The protective cover on round slings hides the load-bearing fibers, which can make inspection for damage more challenging compared to flat slings.

Flat Slings

Construction: Flat slings are constructed from layers of webbing material sewn together to form a flat, wide sling. This design provides a broad surface area that can help to spread the load and reduce pressure points.

Load Distribution: The wide surface of flat slings is excellent for spreading loads over a larger area, which can be beneficial when lifting items that are prone to damage from concentrated pressure.

Load Capacity: While flat slings offer good load capacities, they generally do not match the load capacity of round slings of the same material and size.

Versatility: Flat slings are versatile and can be used in various hitch types, including vertical, choker, and basket hitches. They are also easier to inspect for damage due to their exposed construction.

Ease of Use: Their flat design makes them easy to position and handle, but they can be less flexible around curved or uneven loads compared to round slings.

Specialized Lifting Solutions: Twin-Path® Heavy Lift Slings

For heavy-duty lifting operations that demand exceptional strength and reliability, the Twin-Path® Heavy Lift Slings are a standout choice. These slings, known for their robust design and safety features, are engineered to handle some of the most challenging lifting tasks.

High Load Capacity: Twin-Path® slings are designed to lift extremely heavy loads with a unique double-path construction that provides redundancy and enhances safety.

Built-In Safety Indicators: These slings come with integrated indicators that show when the sling has been overloaded or damaged, allowing for immediate inspection and replacement if necessary.

Durability: Constructed with advanced synthetic fibers and protective covers, Twin-Path® slings are resistant to abrasion, cuts, and chemicals, ensuring a long lifespan even in harsh environments.

Web Sling Types and Applications

Our range of web slings includes various types tailored to specific lifting needs:

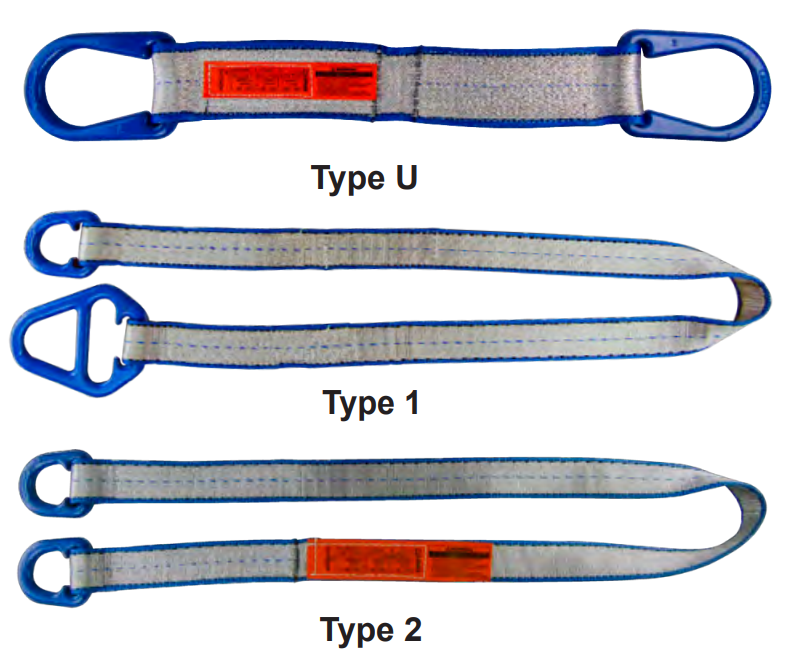

Hardware Slings:

Type U (UU): Economical with Unilink fittings, suitable for vertical, choker, or basket hitches.

Type 1 (TC): Features a Web-Trap triangle and choker, ideal for choker hitches.

Type 2 (TT): Equipped with Web-Trap triangles on each end, primarily used in basket hitches but adaptable for vertical hitches.

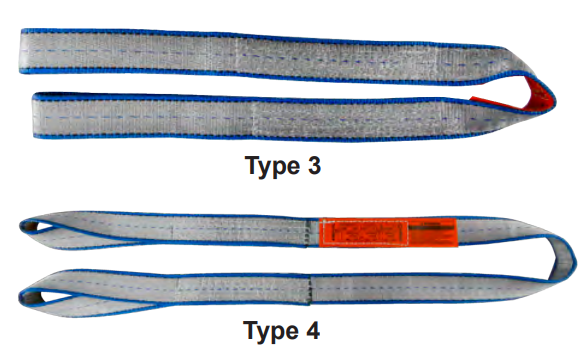

Eye/Eye Slings:

Type 3 (EE): Flat Eye slings, versatile across all hitch types and easy to remove from beneath loads.

Type 4 (EE): Twisted Eye slings with eyes turned 90° for better crane hook nesting.

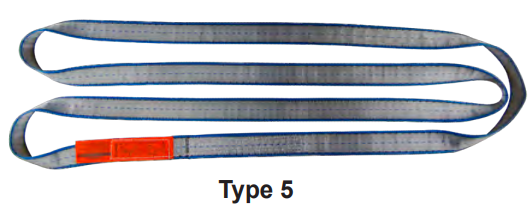

Endless Slings:

Type 5 (EN): Endless slings with reinforced eyes and wear pads, highly versatile and economically priced, suitable for various hitch types.

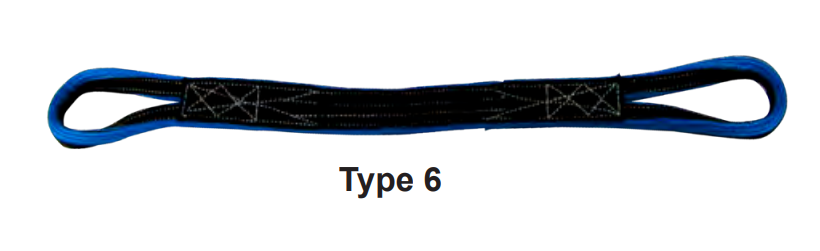

Reverse Eye Slings:

Type 6 (RE): Crafted by sewing together butted edges to double the width, featuring reinforced eyes and wear pads for enhanced wear resistance.

Eye Treatments for Enhanced Durability

To extend the life of your web slings, MTN Industrial offers specialized eye treatments. These treatments use wear-resistant materials to reduce damage from rough crane hooks, ensuring long-lasting performance and safety. For Type 3 and Type 4 slings, tapered eyes are standard for slings 3" and wider. Our eye treatments include additional protective pad materials available in our Sling Protection section.

Environmental Considerations

Web slings are susceptible to environmental factors that can impact their performance and longevity:

Abrasion and Wear: Slings are treated for abrasion resistance, but heavy-duty options are available for enhanced protection. Regular inspection for wear and tear is essential.

Sunlight and UV Exposure: UV exposure can degrade sling materials over time. Regular inspection and proof-testing are necessary for slings exposed to sunlight.

Chemical Exposure: Many chemicals can adversely affect sling materials. Understanding the chemical environment and choosing the appropriate sling material (nylon or polyester) is crucial.

Temperature: Both nylon and polyester slings degrade at temperatures above 200°F. It is important to consider the operating temperature range when selecting slings.

Ordering Your Web Slings

When placing an order for web slings, specify the sling length, width, material, number of plies, type, and any desired eye treatments. Proper selection and use of slings, coupled with adherence to safety protocols, are imperative for safe and efficient lifting operations.

Contact Us

For inquiries or assistance with selecting the right web slings for your needs, please email us at info@mtnind.com or call us at (888) 516-0737. Trust MTN Industrial to elevate your lifting operations with our reliable and efficient web slings.