Understanding Different Types of Industrial Conveyors and Their Applications

Industrial conveyors are vital components in the material handling systems of many industries. This guide focuses on specific types of conveyors, outlining their features, applications, and benefits so that you can make an informed decision when it comes to choosing the most suitable option for your applications.

Fabric Belt Conveyors

Fabric belt conveyors serve as the cornerstone of efficient material transportation, using a fabric belt to move items along production lines. These conveyors accommodate a wide array of materials and products. Choose from various belt materials, including nylon, polyester, or PVC, tailored to your specific operational requirements. Whether you need enhanced gripping capabilities or features like magnetism or vacuum properties, fabric belt conveyors deliver optimal performance.

Applications

Food Industry: Handling packaged and unpackaged food products

Manufacturing: Transporting raw materials and finished products

Pharmaceuticals: Moving delicate pharmaceutical products

Pros

Versatile and customizable

Smooth, continuous operation

Capable of handling a variety of materials

Cons

Requires regular maintenance to prevent belt wear

Limited load capacity compared to heavy-duty systems

Flexible Chain Conveyors

Flexible chain conveyors offer maneuverability in confined spaces, making them ideal for intricate assembly processes and packaging lines. Crafted with durable plastic chains capable of bending and twisting around corners, these conveyors navigate obstacles with precision. Their space-saving design and versatile applications make them valuable assets in optimizing operational efficiency.

Applications

Packaging: Moving products through various packaging stages

Pharmaceuticals: Transporting medicines and medical products

Assembly Lines: Handling components in tight spaces.

Pros

Space-saving design

Versatile and adaptable

Easy to install and modify

Cons

Limited load capacity

Potential for chain wear and damage

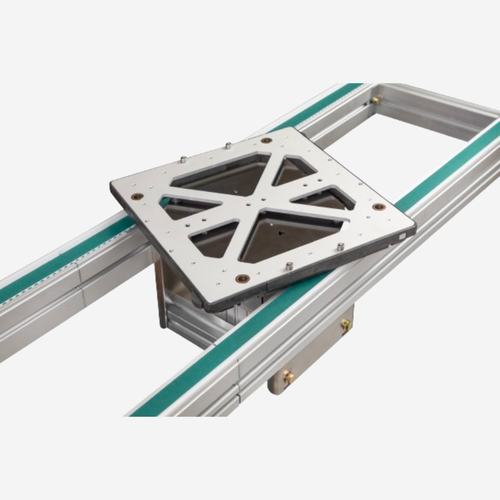

Pallet System Conveyors

Designed for heavy-duty palletized load handling, pallet system conveyors are efficient and precise. They feature industry-compatible pallet sizes and intelligent pin tracking systems, ensuring seamless material flow and logistics management. From warehouse operations to manufacturing facilities, pallet system conveyors streamline processes and enhance productivity.

Applications

Warehousing: Moving pallets within storage areas

Manufacturing: Handling palletized products

Distribution: Transporting goods to shipping areas

Pros

Robust and durable

Suitable for heavy loads

Efficient logistics management

Cons

Requires significant space

Higher initial investment

Sanitary & Stainless-Steel Conveyors

Sanitary and stainless-steel conveyors are designed for industries where cleanliness is paramount. Made from stainless steel and durable plastic components, they offer easy cleaning and sanitation, making them ideal for food processing and medical applications. They also provide durability and regulatory compliance in demanding environments.

Applications

Food Processing: Transporting food products while maintaining hygiene

Medical: Handling medical devices and products

Pharmaceuticals: Moving medicines in a sterile environment

Pros

Easy to clean and sanitize

Compliant with hygiene standards

Durable and long-lasting

Cons

Higher cost compared to standard conveyors

Requires regular cleaning and maintenance

Accumulation Conveyors

Accumulation conveyors provide seamless product storage without disrupting material flow. These conveyors offer a designated space for products to accumulate, preventing jams and damage while optimizing workflow efficiency.

Applications

Warehousing: Storing products before shipping

Manufacturing: Holding products temporarily during production

Distribution: Managing product flow in distribution centers

Pros

Prevents jams and damage

Enhances workflow efficiency

Suitable for various industries

Cons

Requires precise control systems

Higher complexity and maintenance

Conclusion

Choosing the right conveyor system depends on the specific requirements of your operation. Whether you require the versatility of fabric belt conveyors or the hygiene standards of sanitary conveyors, understanding the features and applications of each type can help you optimize your material handling processes for maximum efficiency and productivity.

Contact Us

For more information on Industrial conveyors, please don't hesitate to email us at info@mtnind.com or call us at (833) 721 3165. You can also request a quote via our Contact Us form. Our team is ready to assist you with expert advice and support.